First Class Medical Filter Manufacturing

Our wealth of experience within this sector has led us to providing our customers with first class solutions bespoke to their application requirements.

We provide the very best level of tailored performance for any given filter application. The majority of our standard media grades have Bacterial/ Viral Filtration Efficiencies (BFE/VFE) in excess of 99.999%.

Our product design team will assist our customers in maximising their filtration performance within the space envelope of the application.

Filtration Media

- Specialists in composite filtration technology, unique in our field, our exclusive range of HEPAC® (High Efficiency Particulate Arrestance Composite) medias, combine materials such as glass fibres, activated carbon impregnated cloth, cellulose, E-PTFE, PVDF and many others.

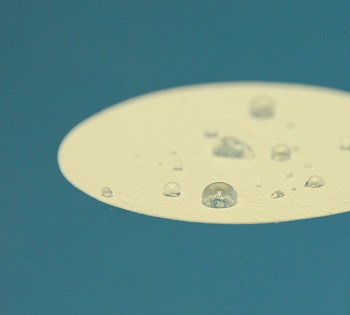

- Various surface treatments available to enhance performance and to provide specific characteristics such as hydrophobicity.

- Efficiency levels increased through the electrostatic polarisation of fibres.

- Standard membranes materials specifically developed for hydrophobic applications.

Activated Carbon

To complement our particulate filtration medias a variety of loose fill activated carbons can be adapted for specific chemical gas applications, where the microporosity of the carbon absorbs the precise gas leaving the remaining air purified and suitable for breathing. Activated carbon can also be used to remove odours, smoke and in aerosol scavenging applications such as anaesthetic gas scrubbing.

Our specialist knowledge in carbon bed integrity ensures that the performance of the carbon material is not compromised through poor execution of the production process. Instead, our activated carbon products offer the very best functional life within their given application.

Filter Elements

Our filter elements are manufactured using several methods, either stamped or thermally cut from the master roll. The thermally cut pads offer a stable heat sealed edge which is often desirable for medical applications where fibre and particle control are a top focus.

We manufacture replacement filter elements as standard offerings to suit OEM equipment or bespoke to our customers specific requirements, including a range of CPAP/BPAP equipment. Prototypes can be offered from our standard range of stocked media’s and using our gas shrouded laser can be precision cut to bespoke profiles and dispatched within the same day.

Heat Moisture Exchange

Used either as a supplement to our filter medias or individually, our Heat & Moisture Exchange (HME) elements capture and retain the humidity of exhaled breath which is then recycled into the inspiratory flow of clean air and gas, ensuring comfort for the patient. Using open cell reticulated foam with the option of Calcium Chloride impregnation.

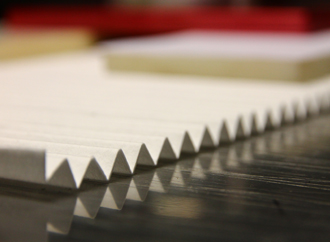

Pleated Filter Elements

With decades of experience in the design of pleated filtration elements, we are able to offer our expertise to assist our customers in maximising their filtration performance within the space envelope of the application.

Media Samples

Samples can be offered from our standard range of stocked medias and using our gas shrouded laser can be cut to bespoke profiles and dispatched within the same day.

Various packaging formats can be offered for our range of products with customer specific labels or printed bag artwork.

OEM Projects

Our experience within medical filtration allows us to offer competitive lead times for the design and development of new products.

We have the capabilities to design and 3D model in-house to create injection moulded components and associated tooling. We can offer our many years of filtration and process experience to advise our customers on their new product development and this could be in a form that sits anywhere between acting consultant, to the role of complete project management and manufacturing partner.

Our in-house manufacturing capabilities provide us with the flexibility to respond to the requirements of our customers whilst maintaining the quality of the end product.